CAE & Simulation Driven Services

Progress and innovation are continuous processes. Self-improvement is in human nature and is often projected outwards as we try to improve on methods, practices, processes and performances.

At Keyway Engineering, we understand that innovation and progress drive the industry and is a necessity. Be it for efficiency or performance, economics or reliability, we are committed to the quest for excellence and engineering design is at the heart of it.

Equipped with the knowledge of performing critical engineering analyses our creative engineers will provide you with the best solutions that conform to international standards like ISO, ASME, DIN, ASHRAE, ASTM, IEEE as well as numerous regional standards depending on our client’s requirements.

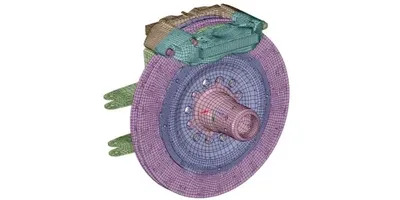

Meshing/ Pre-Processing:

Meshing of components for simulation can be time consuming and challenging. Nevertheless, correctly meshed parts are crucial for achieving accuracy in simulation. We offer our meshing services that allows our clients to focus more on the engineering part. With our team of experts, we provide high quality meshed parts that offer good accuracy with minimal computational cost.

Structural Analysis:

Incorporating simulation based structural analysis early in the design cycle can save costs, reduce the number of design cycles and time to market. Our team of CAE experts provide complete structural analysis solutions using advance simulation tools.

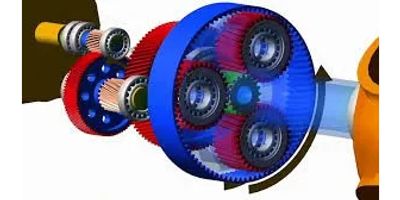

Dynamic Simulation:

We offer dynamic simulation solutions for the in-depth analysis of complex dynamic systems. Whether it’s a drivetrain system or a crane, using multibody simulation, not only can we simulate the motion of moving components, but we can also determine the loading configuration that can transferred for a detailed component level FE analysis.

Fatigue Analysis & Life Estimation:

Our team of experts can help determine the expected life of your product. Using simulations for fatigue analysis, we can identify critical failure zones that will help you make the right decisions for enhancing product life early in the design cycle.

Thermal Analysis:

Using powerful finite element tools, we provide expertise in performing thermal analysis for conduction and convection heat transfer scenarios.

Vibration Analysis:

Machine vibrations and noise are important design aspects that engineers need to consider during the product development. Our team of vibration experts can provide you with deep insights about your product’s dynamic characteristics and vibration behavior that will aid you in improving your design.

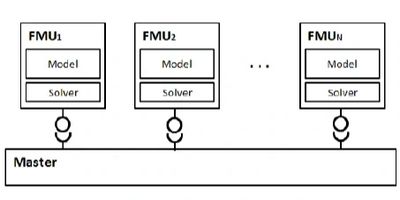

Co-Simulation:

We also offer the opportunity to perform coupled simulation for analyzing the complete system behavior. This includes the integration of multiple dynamic systems and with control systems.